Cutting Optimization Pro: The Ultimate Software Solution for Efficient Material Cutting Layouts (1D & 2D)

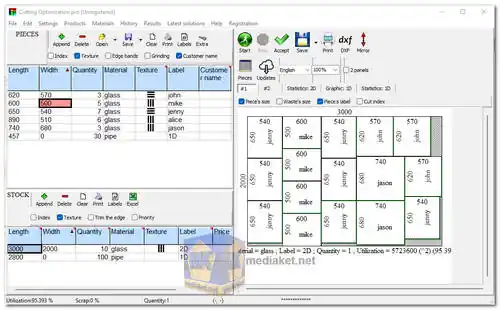

Cutting Optimization Pro is an advanced cutting software designed to maximize material usage by creating optimal cutting layouts for both one-dimensional (1D) and two-dimensional (2D) pieces. Ideal for industries working with materials such as glass, wood, metal, and plastic, this versatile software offers exceptional features tailored to the needs of professionals in furniture, manufacturing, construction, and more. It efficiently handles complex shapes and layouts, making it indispensable for crafting items like tables, desks, shelves, and custom industrial designs. Cutting Optimization Pro can streamline workflows, reduce waste, and ultimately lower material costs.

Key Features of Cutting Optimization Pro:

- 1D and 2D Optimization:

Cutting Optimization Pro offers a unified platform for both 1D and 2D cutting tasks. This makes it highly flexible, allowing users to optimize linear cuts for materials like pipes, metal bars, or wood boards, as well as complex 2D cuts for rectangular sheets of glass, wood, or metal. - Guillotine Optimization:

This feature enables cuts to be made straight across from one side to the other, a must-have for precise material handling in glass, wood, and other sectors requiring clean cuts. - Non-Guillotine (Nested) Optimization:

Ideal for complex shapes, this nested optimization feature allows the cutting machine to follow the material’s shape rather than restricting cuts to straight lines. This capability is perfect for intricate designs, requiring machinery equipped with laser or flame blades. - Multi-Stage Guillotine Cutting:

With multi-stage guillotine cutting, users can plan cuts that are perpendicular in each stage, defining the number and direction of each stage’s cuts. This feature significantly enhances control and precision, allowing for more complex layouts. - Inventory and Demand Management:

Cutting Optimization Pro supports virtually unlimited inventory and demand management, allowing users to manage a large quantity of materials and pieces for high-efficiency production. - Flexible Measurement Options:

This software supports multiple measurement formats, so users can enter dimensions in any metric of their choice without requiring conversion. Fractional input is also supported, allowing dimensions to be entered as 100.5 or 100 1/2. - Customizable Blade Thickness:

For increased accuracy, blade thickness can be adjusted according to the material being cut. Whether it’s a 0-thickness blade for diamond-cut glass or thicker saw blades for wood and metal, Cutting Optimization Pro ensures precise layouts with minimal material loss. - Adjustable Optimization Level:

Users can control the number of layout iterations to fit their system’s capacity and available time. This feature enables the software to run efficiently on various computer types, from standard systems to high-performance processors. - Maximum Cut Length Limit:

For manual cutting tasks, users can set a maximum cut length, enabling better control over material usage and ensuring safe, manageable cuts.

Benefits of Using Cutting Optimization Pro:

- Maximizes Material Efficiency: Significantly reduces material waste, saving both resources and costs.

- Optimizes Workflow: Streamlines the cutting process with tailored settings, suitable for both simple and highly complex projects.

- Increases Flexibility: Can handle various materials and layouts, making it adaptable to diverse industry needs.

- Reduces Setup Time: The software’s user-friendly input options and flexible measurement formats reduce setup time, leading to faster project completion.

Optimize Your Cutting Process with Cutting Optimization Pro:

Cutting Optimization Pro combines cutting-edge technology with a straightforward interface, making it accessible to both seasoned professionals and newcomers. It’s the go-to software solution for any industry looking to optimize material usage, improve productivity, and save on costs.